- #CNC HOTWIRE CUTTER SOFTWARE HOW TO#

- #CNC HOTWIRE CUTTER SOFTWARE MANUAL#

- #CNC HOTWIRE CUTTER SOFTWARE PRO#

- #CNC HOTWIRE CUTTER SOFTWARE SOFTWARE#

Its good idea to make separate routes for inner cut, outer cut and side cuts, then select them in willing order and make GCODE for CNC. When used along with the TurnTable or the Lathe, the ShapeWire Tool enables the operator to cut all kinds or grooved, chiseled, hollow and symmetrical shapes. To generate GCODE, you need to select route (or number of routes in needed order) and execute "MakeGCODE" command. Hot wire CNC Foam machine software-controlled, fully-computerized ShapeWire Tool is an optional device available for most our Hot wire CNC foam c utters. Route - Set of objects above, selected in proper order. Move - Something like path, but offset (X, Z) from point (usually from path endpoint). Rotation - rotate table by given degreeĥ. Exit - same as enter, but reverse directionĤ. Enter - Move to entry point on safe height and then enter pathģ. Path - Cut movement by curve-curve and point-curveĢ. Simulation is very simple to implement, but this feature just interesting and really not very usefull.ġ. Also I'm not satisfied with workflow, user experience, and algo for path generation, so thats a reasons for me to create my own set of tools for hotwire. The foam cutter build is is also a stepping stone towards a CNC router that can handle aluminum.I know NiCr workbench and it "dead" not only because it not works under current FreeCAD versions, it not fits my needs like handle 5-th axis (rotary table), wire on/off, and dynamic wire power management. I bet for every one good build is 100 bad builds. Most people are not going to be able to make the parts accuratly enough. I do not care for all the wood/mdf do it on a drill press ideas out there. Well enough to know I want to cut foam, not make it an electronics project. The operator runs the machine through its software, using the touch. even though I am well versed in C and general controller "stuff". Designed to cut through expanded polystyrene our Hotwire. because just building and assembling the machine is enough work. got two pieces "just cause" and decided I will use them for X axis.īTW, At first I selected Nema 17, then changed my mind and got 23 size. I won't use it for the future (hopefull) cnc router build.

well compared to other extrusions I have from 8020 and the scrap yard. The opnebuilds extrusions are what I would consider "light" structurally. I am in process of building one, using hardware/extrusions from openbuilds.įor the money it easily competes with the unit you have shown.

#CNC HOTWIRE CUTTER SOFTWARE HOW TO#

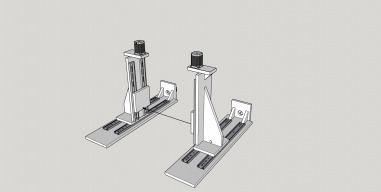

I know how to build the towers for the hot wire and I will control the hot wire separate from the CNC 4-axis electronics. I've bought some stuff today in the hope to build a 4-axis CNC hot wire foam cutter.

#CNC HOTWIRE CUTTER SOFTWARE MANUAL#

3 different types of manual control and steerage. Unlimited material and cutting presets saving. Cut in any direction: from top to bottom from right to left and vice versa.

#CNC HOTWIRE CUTTER SOFTWARE SOFTWARE#

I am an RC plane hobbyist with a preference for big gliders and maybe DLG's, if my nice machine some day will cut the wings for me Small, plug & play, software user-friendly and very accurate, Cream200 is the right cnc foam cutting machine for who is the approaching at the world of foam. Set starting point for cutting at any point of the plotter. Can I use my USB-port on my laptop to control it?įor a long time I have been reading about this subject in several fora, and now I took the decision to buy what I meant was reasonable to get at good beginning on my foamy CNC adventures.Is it good, bad, medium or directly off-the-road-crazy what I found?.You can also get the Gcode in many other ways. Profili is good, because it can create the Gcode for the 4-axis cnc hot wire foam cutter. This cnc hotwire foam cutter is equipped with the software Nettuno, that is able to process advanced cutting process and elaborate complex cuts of foam shapes.

#CNC HOTWIRE CUTTER SOFTWARE PRO#

To generate the Gcode I use Profili Pro from Stefano Duranti Cream200 is a 2 axes machine, but it has included also the vertical turntable (third axis) for cutting also special 2d and 3d shapes (logos, figures, signs, letters) in a quick, accurate and easy way. GcodeSender - Thanks one more to Dan Royer from Get it here: 6 Axis CNC Demo Rumba - Thanks to Dan Royer from Get it here: Hot wire CNC Foam machine software-controlled, fully-computerized ShapeWire Tool is an optional device available for most our Hot wire CNC foam cutters.

0 kommentar(er)

0 kommentar(er)